2023-05-09 Radebeul

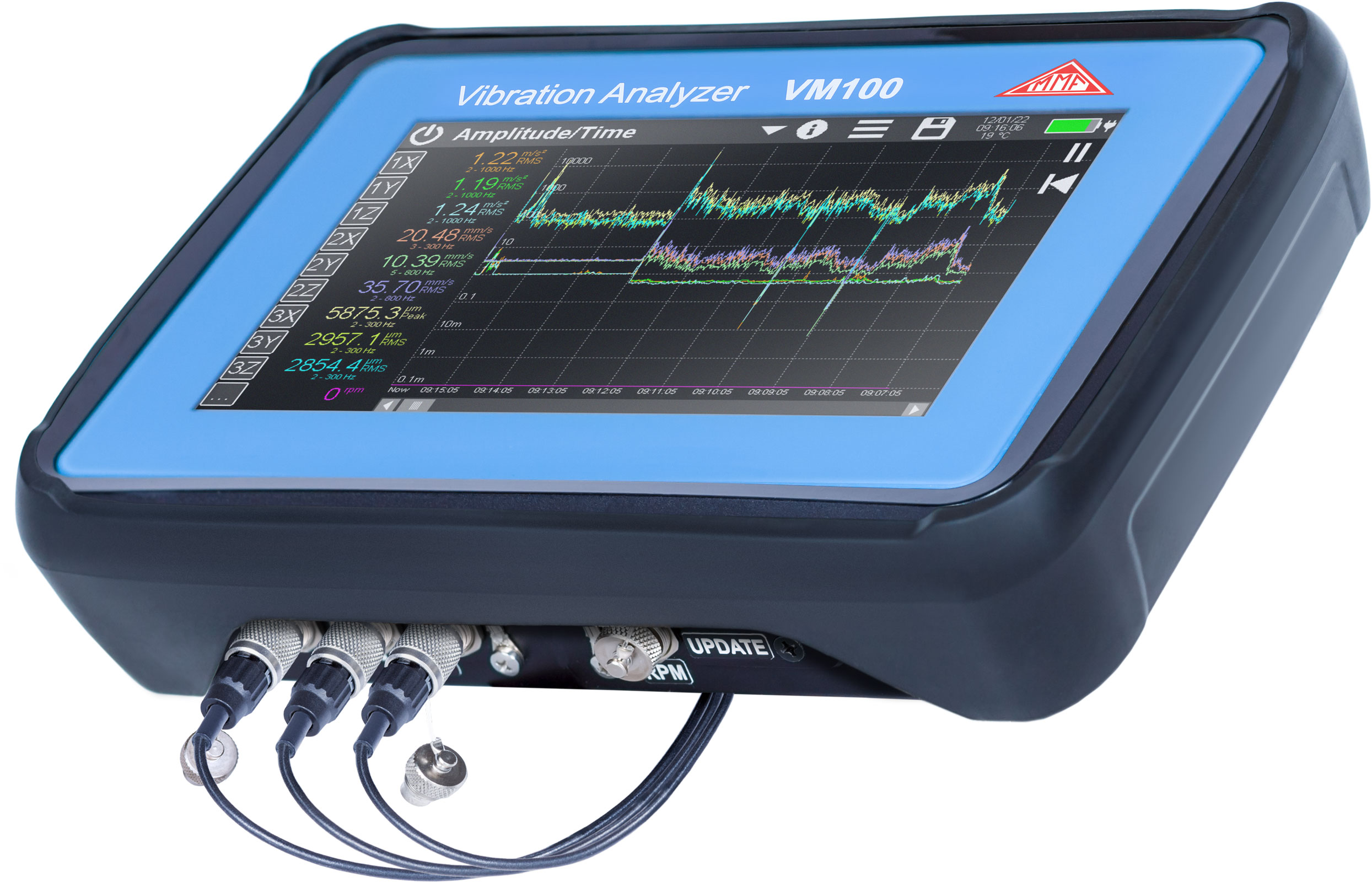

This is a new exciting system from Metra. Available with either 3 or 9 channels with additional tacho input for RPM.

Measure vibration simultaneously for up to 24 kHz with 22 kHz FFT bandwidth.

Amplitude-time plotter and FFT module come standard with the equipment.

Packed with available software modules such as:

- VM100-RPM: Amplitude-rotation speed measurement

- VM100-MAC: Machine vibration and measurement route management

- VM100-ENV: Envelope analysis for roller bearing diagnosis

- VM100-BAL: Balancing in one or two planes

- VM100-VC: Third-octave analysis; VC and Nano criteria

- VM100-HA: Hand-arm vibration measurement

- VM100-WB1: Whole-body vibration measurement

- VM100-WB3: Whole-body vibration measurement with 3 sensors