MSR175

Shock Transportation Data Logger: MSR175

- Shock data logger with 2 acceleration sensors ±15 g and ±200 g

- Temperature, humidity, air pressure and light sensors available

- Stores 2 million total readings

- Air cargo approved

Whether it be to verify questions of liability, detect damage early or to optimise packaging: The MSR175 data logger accurately records critical transport events such as shocks, jolts or fluctuations in temperature, pressure or humidity and provides clarity with objective measured data.

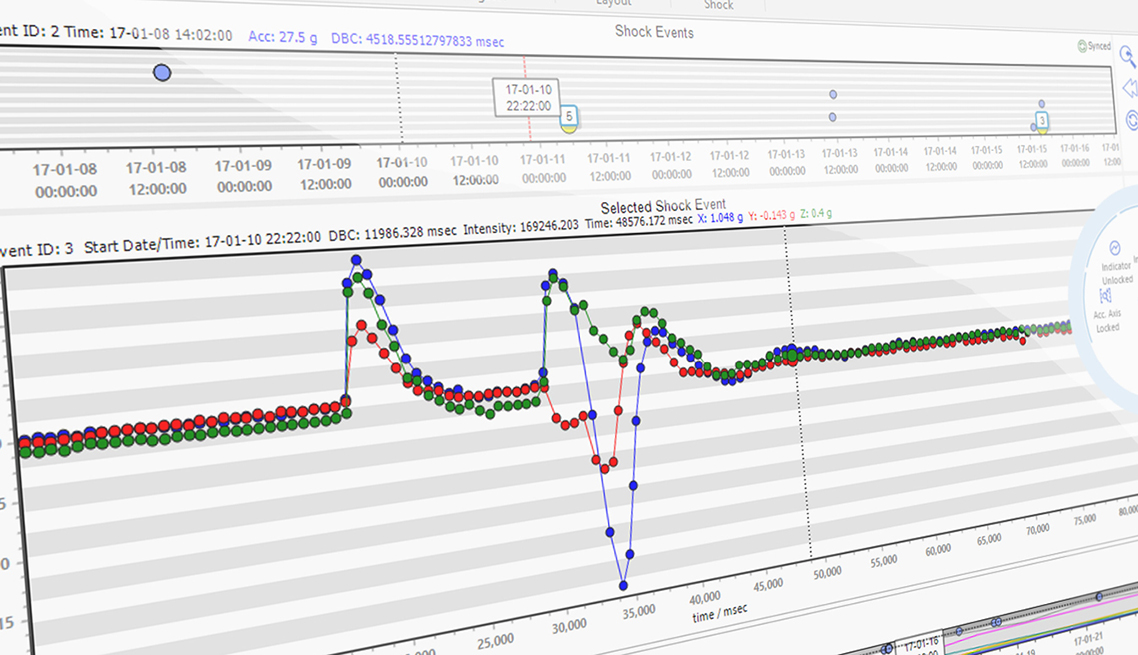

Transportation monitoring, documentation of damage during transit

The two digital 3-axis-acceleration sensors (± 15 g and ± 200 g) integrated in the MSR175 record shocks at a measurement frequency of up to 6400/s. The storage capacity of over 2 million measured values is sufficient to record at least 1,000 shocks (230 mAh Li-Po battery) or approximately 1,000 shocks (3.6 V, 7700 mAh Li-SOCI2 battery), depending on the type variant.

In addition, the transportation data logger measures and records temperature profiles from -20° to +65 °C. Further type variants of the MSR175 are available with internal humidity, air pressure and light sensors.

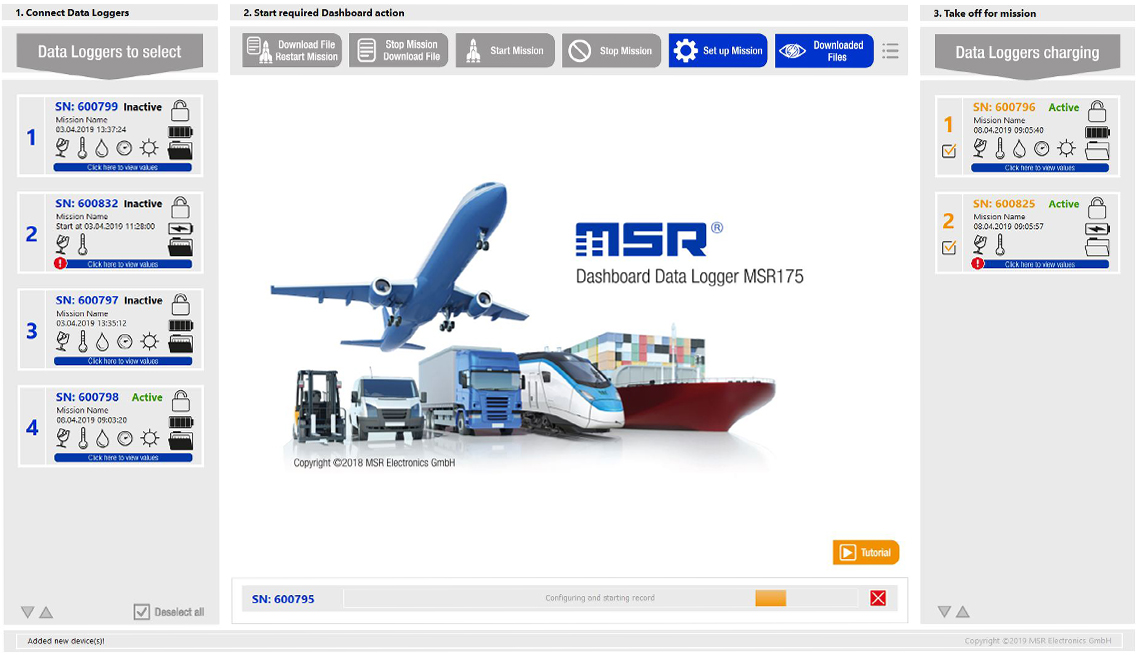

Easy to use: Start the logger, evaluate the data, save costs

The software package for the MSR175 includes 3 programs: MSR175 Dashboard, MSR ReportGenerator and MSR ShockViewer. The MSR Dashboard allows you to configure the logger with just a few mouse clicks. The data recorded can be quickly transferred to a computer via the USB port. A single click on the MSR ReportGenerator is sufficient to call up a compact report. For a detailed measured data analysis, the MSR ShockViewer, which is integrated in the MSR175 software package as a free basic version, is at your disposal.

Product features transportation data logger MSR175

- High-speed shock logger with 2 internal acceleration sensors

- 3 shock measurement modes: either ±200 g at 6400 Hz or ±200 g at 3200 Hz or ±15 g at 1600 Hz

- 1 internal temperature sensor included; depending on the variant, 1 additional internal humidity, pressure and light sensor each; measurement frequency/storage rate every 10 min.

- Installed memory is capable of storing over 2 million measured values

- Setting of limit values

- Rechargeable 230 mAh lithium-polymer battery, recording time of up to eight weeks, or replaceable Li-SOCI2 battery, operating time at least 2 years

- Coloured LED for status indication

- MSR175 software package with Dashboard software for easy start-up of the data logger, MSR ReportGenerator for automatic report generation and MSR ShockViewer for detailed analysis of shock events

| Internal sensor | Working range | Accuracy (max. deviation) | Measurement/Storage rate |

|---|---|---|---|

| 3-axis-acceleration | ±15 g and ±200 g (-20…+65 °C) |

±15 g sensor ±0,15 g (0…5 g, +25 °C) ±0,3 g (5…15 g, +25 °C) ±200 g sensor |

1600/s (±15 %)

3200/s (±15 %) 6400/s (±15 %) |

| Temperature | -20…+65 °C | ±0,5 °C (-10…+65 °C) | every 10 min. |

| Relative humidity |

0…100 % rel. humidity (-20…+65 °C) |

±2 % rel. humidity (10…85 %, 0…+40 °C) ±4 % rel. humidity (85…95 %, 0…+40 °C) |

every 10 min. |

| Air pressure |

0…2000 mbar absolute (-20…+65 °C) |

±2.5 mbar (750…1100 mbar absolute, +25 °C) |

every 10 min. |

| Light | 0…83’000 lx | max. sensitivity at 550 nm | every 10 min. |

General technical data of the MSR175 data logger

| Memory capacity: | Over 2,000,000 measurement values. |

| Medium: | Air |

| Colour: | Amber |

| Key: | Start measurement/retrieve status. |

| Power supply: | LiPo battery 230 mAh, charged via the USB connection, recording period up to 8 weeks or replaceable Li-SOCI2 battery (3.6 V, 7700 mAh), battery operating time 2 years at least. |

| Options: | Charging station (USB hub) for 7 MSR175 (item number B47002). |

| Interface: | USB |

| Software package: | MSR175 Dashboard software, MSR ReportGenerator, free MSR ShockViewer basic version. A fee-based MSR ShockViewer Pro Version will be available at a later stage. System requirements: Windows 7 or higher, USB port. |

| Operating conditions: | |

| Temperature: | -20…+65 °C |

| Storage conditions: | |

| Temperature: Humidity: |

+5…+45 °C (ideal storage condition for the battery) 10…95 % relative humidity, non-condensing |

| Standards: | The MSR175 complies with EU-Directives RoHS/WEEE. |

Shock Data Logger MSR175: Optimising transport processes, minimising the consequences of damage, saving costs

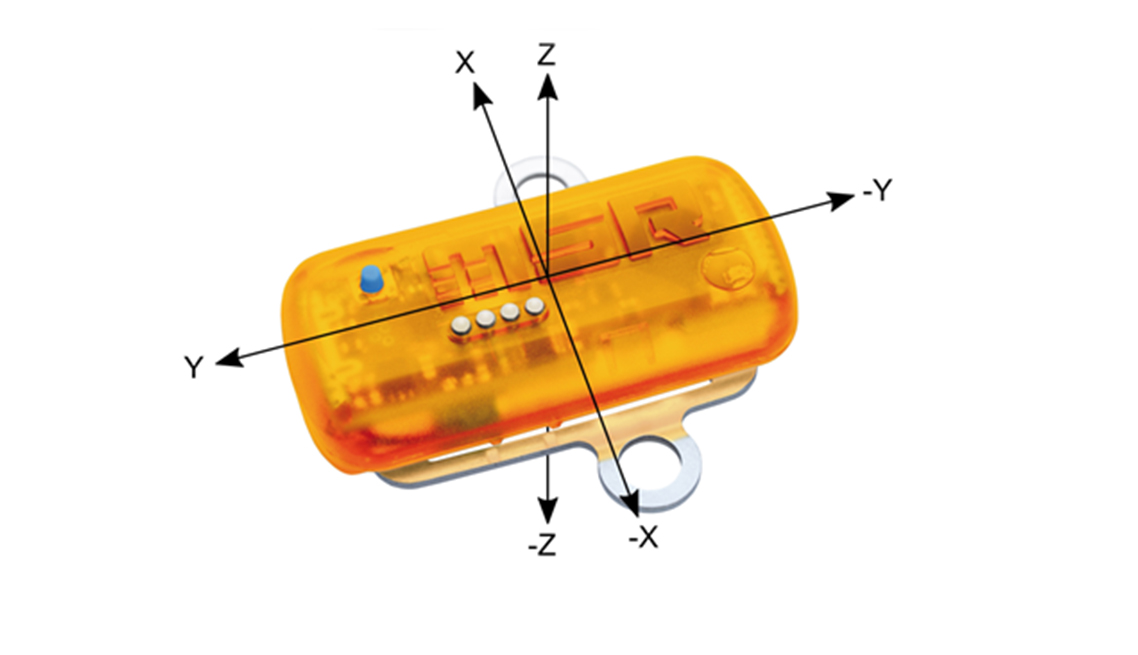

The most important physical parameter that should be monitored in a transport and logistics chain are accelerations. Shock events can have a negative effect on the mechanical structure of any industrial object or commodity. The MSR175 shock data logger helps to uncover the causes of damage. The most important physical parameters that should be monitored in a transport and logistics chain are accelerations. Shock events can have a negative effect on the mechanical structure of any industrial object or commodity. MSR175 data loggers help to uncover the causes of damage. In the course of any transport, extremely costly damage can occur to sensitive goods such as electronic products, machines or works of art due to improper handling. This may result in loss of sales due to defective goods, unplanned subsequent production and considerable claims for damages due to delayed production start-up or inability to deliver. In order to be able to accurately record and conclusively document high-risk transportation stresses, such as shocks or knocks, the corresponding acceleration value should be recorded more than 1,000 times per second. This also enables you to capture and analyse jolts in their frequency characteristic. With its two acceleration sensors (±15 g and ±200 g) and high measurement frequency of 6,400 measurements/s, the MSR175 shock data logger meets this criterion as well as the requirement to obtain acceleration values in all directions (x, y, z).

Checking and documenting prescribed limit values

Not only can goods be damaged by shocks or vibrations during their transport, they are also exposed to temperature, pressure and humidity fluctuations, which pose a risk. MSR175 transportation data loggers can also be used to accurately record climatic values and subsequently, to evaluate and archive these values very easily, using the automatic report generation feature. Ultimately, the MSR175 transportation data logger helps you to accurately identify problem events and thus save significant costs.