imc ONLINE FAMOS

imc ONLINE FAMOS is software package, an extension of measurement and data acquisition systems from imc Meßsysteme, enabling the digital signal processors in the device to perform complicated mathematical functions.

Built-in real-time analysis & control

Collecting buckets of raw data is a start, but are you also interested in seeing instant results and real time system response from your test system? If so, you might like to learn more about imc Online FAMOS.

Data processing & analysis

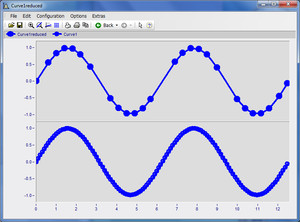

imc Online FAMOS enables the transformation of raw measurement data into immediate information within the measurement system itself, without any help or reliance on an external PC. imc Online FAMOS can perform synchronized mathematical calculations on live data from multiple channels; calculate and record signal statistics; as well as perform comparison operations and deterministic advanced open loop and closed loop control.

In this way, imc Online FAMOS saves you time and money, minimizing your time to test by allowing you to immediately “see” if your test is working and eliminating, or at least markedly reducing, the need for post-acquisition data crunching and subsequent analysis work.

Fast, on-the-spot decisions

Frequently, a test’s progress directly depends on the measured values and their resulting analysis. imc Online FAMOS can eliminate delays between the capture of data and the start of the decision process. The results from streaming calculations and other analyses are available immediately, as the data is collected and analyzed without interfering with the ongoing measurement. This allows the progress of the test to be monitored, and altered if necessary. For instance, a driver on a test track may decide while driving if a test cycle must be repeated to meet test conditions, or if the test cycle may proceed—without the time wasting effort of driving back to the garage first, waiting for the data to be analyzed, only to discover a test needs to be repeated. And neither the analysis nor the display of the results requires any PC: an imc Display unit connected with any of the imc Data Acquisition Systems is all that is needed to see what is going on.

Closed loop and open loop control, with real-time system response

While decision making requires response times which are fast by human standards, in successful direct feedback control the measurement and control device’s response must be a fraction of a millisecond. Thus, test personnel can be immediately informed about the current state of a test or measurement, even while the measurement device can independently intervene in the test procedure. This saves time and money, as imc Online FAMOS, combined with the digital and/or analog outputs of the imc data acquisition systems, makes any imc device a comprehensive and synchronized measurement and control system, without the need to synchronize or interface to additional external hardware.

It’s that easy

Unlike a fixed purpose analyzer, imc Online FAMOS is easily adapted to the way you work and the tests you need to perform. In total, there are over 150 functions and operations available, which may be combined in virtually any configuration to produce and save a wide variety of virtual channels and calculated values. And since the results are continuously calculated from streaming measured data, “virtual” channels can also be used as part of the control system or to define sophisticated triggering conditions for the measurement itself.

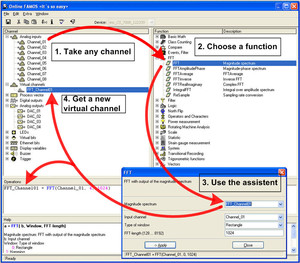

All functions can be accessed with one mouse click, thanks to the imc Online FAMOS Formula Assistant. Since no specialized programming language skills are required, the imc data acquisition systems may be configured by any user with little or no training.

| Online calculations allow you to define your own operations and control |  | Over 150 functionsUser defined calculationsResults in real time: no dependence on PC or network interface in critical tasksFunction wizard: makes all operations “as easy as using a pocket calculator” |

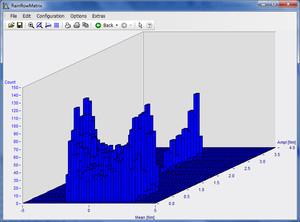

| Class-counting (Optional Extension) |  | Signal class counting for fatigue and durability cycle testingOn-the-fly classification histogram(s)Rainflow algorithmTwo-channel revolutions matrixExtreme value approximation |

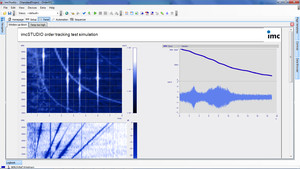

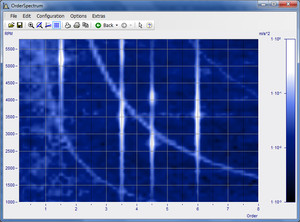

| Order-tracking analysis (Optional Extension) |  | Spectral analysis of vibrations associated with rotating machinesOn-the-fly order spectrum, magnitude or magnitude & phase Determines RPM-value/frequency linePulse time measurementAngle based smoothing |

| Controller (Optional “Pro” Extension) |  | Enhanced hard real time feedback-type control, including:PID-controllerTwo-point controllerController output limitingController block |

| Transitional recording and event tracking |  | Up to a 250-fold reduction of data volume with minimal loss of resolutionData points recorded if necessary to prevent significant deviations from the actual data valuesRecord Event stores textual data along with timestamp for automatic log book of significant data or events |

| Basic operations, signal math, filters, and FFT |  | Signal arithmetic and calculus as easy as using a “pocket calculator”Software configurable high and low pass filters, along with band pass, band stop, and arbitrary IIR & FIR digital filtersOn-the-fly Fast Fourier spectral calculation for magnitude or magnitude and phase spectra; inverse FFT |

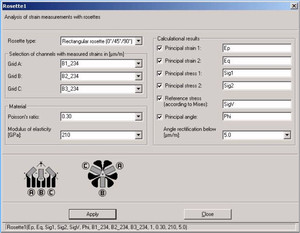

| Multi-channel synchronous calculations |  | Calculation of principle strains and angles with rosettes in real time Single, two and three phase power calculations in real timeIntuitive function assistant guides you through the inputs and output of the function |