Strain Gauging

Invicom Test & Measurement provides dependable strain gauge (strain gage) installation service, and strain gauge measurement service for static or dynamic tests. No matter how challenging the requirements are, our long experience in the field will certainly help running the test smoothly.

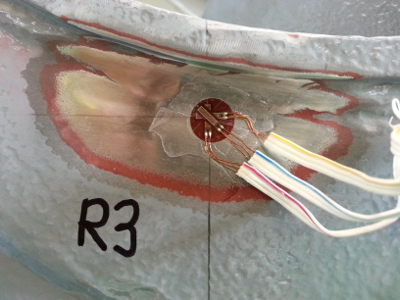

Our services include from the determination of strain gauge locations, gauge attachment, protection, shielded wiring, calibration, signal conditioning, data acquisition and processing of measured data.

We are able to do the work either with small channel counts or hundreds of simultaneous dynamic channels, with low turn around times and work schedules that can synchronize with your test/installation timeline.

According to your requirements, we will give technical recommendation on number of strain gauges, locations, orientations, type of Wheatstone bridge to use, weatherproofing, and wiring issues.

We can also conform to your engineering requirements, on the exact positioning and gauge lengths; as well as ISO or JEDEC 9704 test specifications.

Our measurement systems are capable of acquiring other types of signals (IEPE acceleration, voltage, current, frequency, GPS, CANBUS, OBDII etc) in sync with strain signals for comprehensive analysis of the measured data.

With years of experience, we can determine which methods, materials, techniques and procedures are to be applied for your testing success.

Our services and solutions for strain gauging are highly regarded by the customers due to:

- Strict work discipline and attention to detail

- Experience in handling large number of channels with long cable runs

- Flexible scheduling

- Provide entire solution from gauging, cabling, data acquisition to measurement results.

- Fast turn around time

We have been doing the strain gaging work not only in Malaysia, but also in all the countries where the work is located. Our engineers are willing to travel with the complete measurement system for doing tests anywhere. We have successfully performed measurements in the middle-east, Indonesia, Thailand, Singapore besides Malaysia.

Strain gauging is just first step of a measurement campaign, accurate measurement of the strain values is important for successful measurement.

State of the art data acquisition systems from imc Test & Measurement GmbH were used for reliable continuous measurement of strain for complete loading cycles. Measurements can be performed during rain or shine, considering a typical loading cycle for a structural test can be days. Our measurement systems do not depend on a computer for data capture, rather, the systems operate on their own with internal storage. This ensures the data integrity and makes it possible for unattended long measurement durations.

Last Updated on January 12, 2026 by Invicom Webmaster