Vibration Monitoring

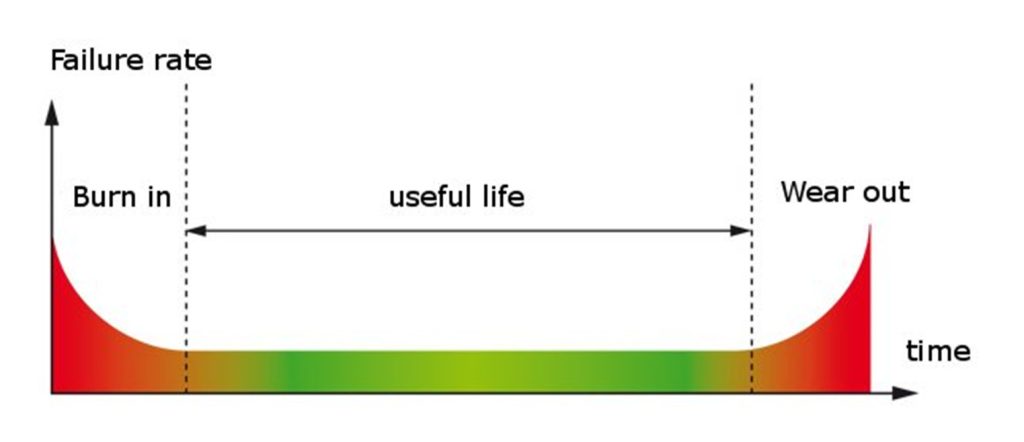

Running machines need maintenance. Some maintenance programs call for the machines to run till failure or do some sort of periodic service after certain hour-runs, while others add more intelligence.

Invicom provides condition based monitoring systems for predictive and pro-active maintenance, where the machine itself “cries” for help. Sensing, recording, processing and understanding such signals from the machine becomes our study.

Vibration of a machine is an excellent indicator of the machine condition. Vibration signals must be captured at correct locations, with good sensors, proper cabling and measurement systems.

Our monitoring systems process these captured vibration signals in real-time to see in-depths for faults such as Imbalance, Misalignment, Belt Misalignment, Structural Looseness, Mechanical Looseness, Bearing Wear, Blade/Vane Pass, Worn Gears, Chipped/Broken Gear Teeth, Misaligned Gears and resonance issues.

Invicom enhances traditional measurement techniques with real-time data processing and indicating systems for instant results.

These systems can be stand alone or distributed iot systems with AI integrated cloud architecture, that processes and predicts the faults. This helps our customers keep their machine running optimally with reliable vibration monitoring systems.

Vibration monitoring as part of a predictive maintenance plan allows for the prediction of machine breakdown and will thereby save maintenance and downtime costs. The ISO 10816/20816 family of standards deals with measurement and evaluation of machine vibration.

ISO 20816-1 specifies the RMS of vibration velocity (severity) from 10 to 1000 Hz as an indicator of unbalance. It shows permissible values for different machine types with different sizes, foundations and speeds. ISO 10816-3 indicates vibration velocity limit values for large machines up to 50 MW.

ISO 10816-6 deals with reciprocating machinery. Their vibration is typically measured in three directions between 2 and 1000 Hz as RMS values of acceleration, velocity and displacement. This standard also gives reference values for different machine conditions.

ISO 10816-7 classifies vibration velocity limits for rotodynamic pumps.

Apart from these given limit values, predictive maintenance experts often use their own methods and limits.

Roller bearing condition monitoring is far more complex matter than unbalance for example. Only very few standards have been published. A good overview can be found in guideline VDI 3832.

For bearing evaluation usually acceleration in the frequency range above 1 kHz and up to at least 10 kHz is measured.

Powerful but demanding methods are frequency analyses (FFT, PSD etc) and envelope curve formation.

There are also more simple methods based on characteristic variables like RMS and peak values, crest factor, kurtosis factor or K(t) value.

Here is the brief information on the machinery vibration limits according to ISO 10816/20816 family:

Related Items:

Accelerometers

These are vibration transducers for nearly every purpose, including accelerometers with charge and IEPE (ICP) compatible output.

Spectrum Analyser

- Sound Power Level Measurements

- 1/1 Octave and 1/3 Octave Measurements

- Frequency and Time weighing

- Vibration Analysis

- FFT

Last Updated on January 22, 2026 by Invicom Webmaster